Continuous improvement of manufacturing systems

ME-498

Media

This file is part of the content downloaded from Continuous improvement of manufacturing systems.

Welcome to Continuous Improvement (CIP)!

Instructor: Amin Kaboli

Coaches: Gaétan Kaouadji, Jack Pulcrano

Course Summary:

Continuous Improvement encompasses the ongoing effort to capture, create, and deliver value to internal and external customers. This course empowers students to lead teams and harness technology to improve products, services, and processes.

Ground rules

- Course Reference (ME-498): For ease of communication, we use the terms CIP or CIP25 to refer to this course.

- Classes: The lectures and exercises happen every Friday from 13:15-17:00 in room CM 1 5. Other classes listed on the course page are assigned for Coaching rooms and practice rooms.

- Class Participation: This course is very dynamic and based on its structure, it demands your active engagement and participation (85% over the semester). For those who have not attended class, the available off sessions are limited, reducing the margin within your 85%. Therefore, if you choose to accompany us on the CIP journey over the next 14 weeks, we urge you to be fully present, both physically and mentally.

- Decision on "Course Participation": While it is your unequivocal right to explore and assess different courses, please be mindful that you have been assigned to specific groups and are expected to engage actively and submit your assignments by the indicated deadlines. Given these commitments, we encourage you to make a decisive choice promptly. If you choose to engage, please do so respectfully and wholeheartedly; if you opt not to take the course, please withdraw from Moodle and inform the class at the earliest to minimize impact on your group mates. We view clarity and decisive communication as acts of care for oneself and for others.

- Timeliness: Given that we are in Switzerland, punctuality is highly valued and appreciated. Therefore, we kindly request you to arrive 5-10 minutes prior to the commencement of the class at 13:15 or the subsequent sessions at each quarter past the hour (14:15, 15:15, 16:15). After all, if our trains in Switzerland can adhere to their tight schedules and not be late, why should we? Your timely presence not only cultivates a conducive learning environment but also fuels our enthusiasm, enabling us to deliver our very best.

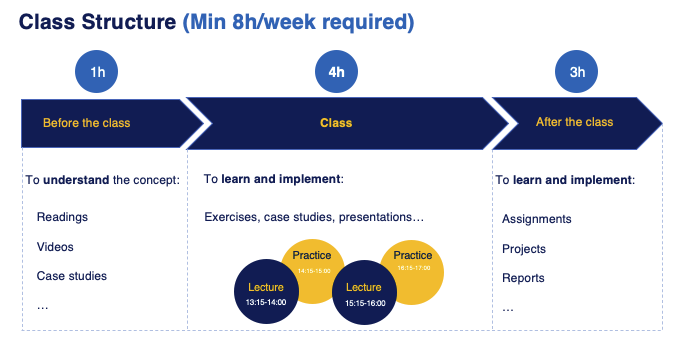

- Class structure: Please note that we follow a flipped classroom approach. You are expected to read the assigned materials in advance and come to class prepared to engage in exercises and case studies that will be provided during the session (See the figure below).

- Weekly Schedule: A full semester schedule is available here; however, please note that it is subject to change. Only the weekly announcements posted on Moodle should be considered final.

- Group work: Working in a group is essential to this course. You are assigned to a group of 4 members (find your name here - Login with your EPFL email). We do our best to (re-)assign you (if needed) to a group as diverse as possible to work together (on case studies, project(s), presentations, and assignments) during the semester. You must ensure your best group performance by setting clear goals, ensuring everybody is engaged, contributing, and staying positive. Your coaches will give you the required directions and instructions on the exercise sessions.

- Professionalism: We expect you to stay professional and consider this time a learning opportunity. It's your responsibility to ensure you are in class on time or there is no technical issue (joining the course on time, simulation sessions, screen sharing, downloading/uploading files, etc.). If you have any problems, please don't hesitate to contact us through Moodle of the course.

- Announcements (Forum)

- Social Forum (Forum)

- CIP Barbecue date (Choice)

- Mock Presentation Proposition (Choice)

Group Evaluations

Continuous evaluation of quizzes, case reports, projects, individual and group presentations, class discussions, during the semester. More precisely;

25% Presence, participation, class engagement

45% Class assignments/projects/cases/quizzes, presentations, reports

30% Final report, final presentation *understanding of the course*

Week 1: Introduction to CIP

- Book Chapter - Operations Improvement (from page 1 to 12) (File)

- Slides-Week 1-Introduction to CIP (File)

- Slides-Week 1-Class Ground Rules – Our Seven Agreements (File)

- Case Study: Nestlé - Play & Practice (File)

- Presentation Evaluation Form (File)

- Learning Support Material - How to ace your presentation? (File)

- Learning Support Material - The art of giving and receiving effective feedback (File)

Week 2: Capacity Planning & Managing Change

- Book Chapter - Capacity Planning & Constraint Management (from page 1 to 11) (File)

- Slides-Session 1, 2, 3 - Capacity Planning & Managing Change (File)

- Lindt Excel Exercises (File)

- Learning Support Material - WEF Harnessing AI (File)

Week 3: Constraint Management

- Book Chapter - Capacity Planning & Constraint Management (from page 12 to 17) (File)

- Slides-Constraint Management & Growth Mindset (File)

- Bottleneck-Explainer (File)

- Business Statistics (Folder)

- Learning Support Material - Book Chapter-Growth Mindset (File)

Week 4: Waiting Line Models

Week 5: Quality Planning

- Book Chapter - Quality Planning (File)

- Book Chapter - Nonviolent communication (File)

- Slide-Quality Planning + Emotional Intelligence (File)

- Learning Support Material: Danny Kahneman “Noise: A Flaw in Human Judgment” (URL)

Week 6: Quality Control

- Book Chapter - Quality Control (File)

- Slides-Quality Control (File)

- Exercises: Quality Management Excel (File)