Seminar series on advances in materials (autumn)

MSE-470(a)

Media

Media

Welcome to the IMX Seminar series.

The following information is only relevant if you want to receive credits for this course or for attending one of the seminars:

(1) If you are an EDMX graduate student, you require at least ten signatures for your candidacy requirement. To get these signatures you must attend at least 10 seminars, either in person (preferred) or virtually (if necessary).

Attendance sheets are available from the EDMX administration.

- For in person attendance, bring your sheet with you and get it signed at the end of each seminar OUTSIDE the seminar room MXF 1 by the course TA, Martin Luttmann (martin.luttmann@epfl.ch).

- If you attend online, sign in to zoom with your full name, so that the TA can verify your attendance throughout the entire seminar. When you require the signatures, it is your responsibility to email the TA your scanned attendance sheet, which they will verify against the zoom attendance list and sign accordingly.

(2) If you are taking the seminar series as a course for credit, you must make sure to be registered on IS Academia but you do not need attendance signatures. The exam will be scheduled during exam session and is based on material provided and presented by the different speakers. This material entails two articles per speaker which are provided on the speaker's Moodle entry. We will divide the speakers into two groups. Ahead of the exam, each student will be asked to select the group on which they will be examined. To prepare for the exam, students should familiarize themselves with the articles provided by the speakers in their selected exam group, focusing on fundamental concepts and major results. Stay tuned for the exam announcement.

(3) Moodle is the primary mode of contact for this course. Please check in regularly.

(4) The Zoom link for this course is:

https://epfl.zoom.us/j/66294920235?pwd=VFROKTtIF5xBjSbj90xa94BH94ePwJ.1

(5) The program can be found at this link and here:

9 September: Manos Kioupakis

Computational Discovery and Experimental Validation of Rutile GeO2 and GeSnO2 Alloys: A New Family of Ultra-Wide-Band-Gap Semiconductors for Power Electronics.

Semiconducting materials play a crucial role in modern society, from information technology and optical communications to renewable energy generation and vehicle electrification. In particular, ultra-wide-band-gap (UWBG) semiconductors, i.e., semiconductors with band gaps wider than the 3.5 eV value of GaN, are promising for higher efficiency, reduced size, and lower cost in high-power electronics applications. For example, materials such as diamond, cubic BN, β-Ga2O3, and AlGaN promise higher conversion efficiency and orders-of-magnitude improvements in power density compared to current technologies (Si, SiC, and GaN). However, none of the above UWBG materials offers all the desired properties needed for high-performance electronics and, despite decades of research, very few alternative UWBG semiconductors have been realized to date. There is therefore a pressing need to develop synergistic methods that combine predictive theory with experimental synthesis and validation in order to discover and design new UWBG semiconductors that can surpass the limitations of current technologies.

In recent years, our team has advanced the development of rutile GeO2 and its alloys with SnO2 as a novel family of UWBG semiconductors that can surpass the state of the art in power electronics. Our predictive atomistic calculations demonstrate that these alloys exhibit superior fundamental properties that overcome the limitations of current materials. Their band gaps span from 3.6 eV for SnO2 to 4.68 eV for rutile GeO2 [1]. They are predicted to exhibit ambipolar dopability, with SbGe, AsGe, TaGe, Hi, and FO acting as shallow donors, while AlGe and GaGe acting as acceptors [2]. The predicted carrier mobilities are high [3], while the relatively light carrier effective masses prevent the formation of self-trapped polarons. The predicted thermal conductivity is also high and surpasses β-Ga2O3, a prediction that we verified experimentally in unoptimized polycrystalline bulk samples [4]. Overall, we find that the predicted Baliga figure of merit of rutile GeO2 (i.e., a measure of the performance of materials in power electronics), modified to account for donor ionization, surpasses all known semiconductors, demonstrating its unique potential for energy-efficient power electronics [5].

Experimentally, we demonstrate the synthesis of single-crystalline GeO2-based thin films and substrates, which are prerequisites for epitaxial devices. Using suboxide molecular-beam epitaxy (MBE), we demonstrate the stability of GeSnO2 alloy thin films over their entire composition range [6], while the development and epitaxy on single-crystalline rutile GeO2 substrates enables the epitaxy of single-crystalline thin films [7]. Overall, our work demonstrates the unique promise of rutile GeO2-based materials for advancing the state of the art in power electronic devices.

[1] J. Appl. Phys. 126, 085703 (2019)

[2] Appl. Phys. Lett. 114, 102104 (2019)

[3] Appl. Phys. Lett. 117, 182104 (2020)

[4] Appl. Phys. Lett. 117, 102106 (2020)

[5] Appl. Phys. Lett. 118, 260501 (2021)

[6] Appl. Phys. Lett. 117, 072105 (2020)

[7] J. Vac. Sci. Technol. A 40, 050401 (2022)

Speaker Bio

Emmanouil (Manos) Kioupakis is a Professor of Materials Science and Engineering and the Karl F. and Patricia J. Betz Family Faculty Scholar at the University of Michigan. He obtained his PhD in Physics at the University of California, Berkeley, and his undergraduate degree in Physics at the University of Crete. He also held a postdoctoral appointment in Materials at the University of California, Santa Barbara.

Prof. Kioupakis’ research group focuses on developing and applying predictive materials-modeling methods to explain and predict the synthesis and functionalities of new semiconductor materials for electronics, optoelectronics, and energy applications. Highlights of his work include pioneering calculations of phonon-mediated quantum phenomena in materials, such as optical absorption in silicon and non-radiative recombination in LEDs, as well as uncovering fundamental insights on the structure-property relationships of modern nitride and oxide semiconductors. He has supervised the PhD research of 21 students of diverse backgrounds, who pursue independent careers in academia, national laboratories, and the microelectronics industry. The courses he teaches at the University of Michigan on the physics and thermodynamics of materials focus on incorporating active-learning techniques into the large-classroom setting. Among numerous positive educational outcomes, these methods have also been demonstrated to increase the retention of female students in Engineering. Prof. Kioupakis has received the U.S. National Science Foundation CAREER Award, the Jon R. and Beverly S. Holt Award for Excellence in Teaching, and the Engineering Class of 1938 Award, the highest honor to early-career faculty in Engineering at the University of Michigan.

During the academic year 2024-25, Prof. Kioupakis is on sabbatical leave from the University of Michigan and is hosted as a Visiting Professor by IMX and IEM in STI at EPFL. Prof. Kioupakis will be hosted by Prof. Nicola Marzari at the Laboratory of theory and simulation of materials (THEOS) and the NCCR MARVEL, and by Prof. Elison Matioli at the power and wide-band-gab electronics research laboratory (POWERLAB). During his stay at EPFL, Prof. Kioupakis aims to engage on a broad range of collaborative research activities on the science and engineering of semiconducting materials and devices, and he is looking forward to fruitful discussions and networking with the EPFL community.

16 September: No Seminar

23 September: Neel Joshi

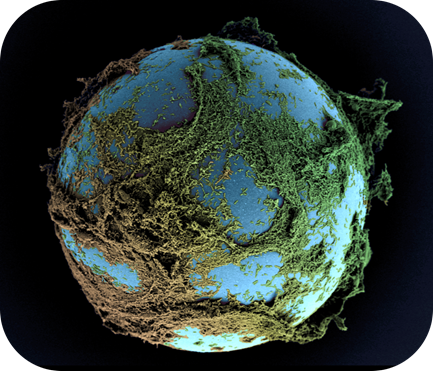

Microbially-driven materials manufacture and responsiveness

Abstract

The intersection between synthetic biology and materials science is an underexplored area with great potential to positively affect our daily lives, with applications ranging from manufacturing to medicine. My group is interested in harnessing the biosynthetic potential of microbes, not only as factories for the production of raw materials, but as fabrication plants that can orchestrate the assembly of complex functional materials. We call this approach “biologically fabricated materials”, a process whose goal is to genetically program microbes to assemble materials from biomolecular building blocks without the need for time consuming and expensive purification protocols or specialized equipment. Accordingly, we have developed Biofilm Integrated Nanofiber Display (BIND), which relies on the biologically directed assembly of biofilm matrix proteins of the curli system in E. coli. We demonstrate that bacterial cells can be programmed to synthesize a range of functional materials with straightforward genetic engineering techniques. The resulting materials are highly customizable and easy to fabricate, and we are investigating their use for practical uses ranging from bioremediation and biodegradable bioplastics to engineered therapeutic probiotics.

Bio

Neel Joshi is an Associate Professor in the Department of Chemistry and Chemical Biology at Northeastern University. He completed his PhD at UC Berkeley in the lab of Matt Francis and a postdoc at Boston University in the lab of Mark Grinstaff before starting his independent academic career at Harvard University and then moving to Northeastern in 2020. He is broadly interested in topics related to biologically inspired materials, protein engineering, self-assembly, and biointerfaces. His group works at the intersection of biomaterials science and synthetic biology. Recent projects in the group have focused on repurposing bacterial biofilms and their matrix proteins for biotechnological and biomedical applications.

30 September: Mark Battley

Boats vs Waves, and Other Ways to Break Composite Materials

Abstract

Due to their light weight, high strength, stiffness and durability, fibre reinforced polymer composite materials are often the materials of choice for high performance and efficient land, sea, air and space vehicles. Mark will give an overview of the University of Auckland’s Centre for Advanced Materials Manufacturing and Design and discuss research projects related to mechanics of composite materials and structures. This will include experimental testing and numerical modelling of water impact of high-performance boats, effects of dynamic and fatigue loads on failure mechanics of laminates, core materials and sandwich structures, and understanding how the way that we manufacture composite materials influences their performance. Mark will also discuss how the techniques developed from this work have led to new areas of research including assessing demisability and re-useability of composite spacecraft, improving recycling and re-use of polymers and composites, using fluid-structure coupling to enhance comfort of additively manufactured foot orthotics, and improving how we mitigate the effects of waves on coastlines and coastal structures.

Speaker bio

Professor Mark Battley, Department of Engineering Science and Biomedical Engineering and Centre for Advanced Materials Manufacturing and Design, The University of Auckland, New Zealand.

Mark did his undergraduate and postgraduate training at the University of Auckland, obtaining a BE (Hons) in Mechanical Engineering and a PhD on the off-axis stiffness characterisation of fibre reinforced plastics. He then worked for 13 years as a Research Engineer at a NZ Government Research Institute (Industrial Research Limited) in Auckland, continuing to have a focus on mechanics of composite materials. During this time, he also spent a year doing teaching and research at the Lightweight Structures Group, KTH Stockholm, Sweden. Mark then worked for the University of Auckland’s Centre for Advanced Composite Materials, while running his own consultancy company. In 2015 he was employed by the University of Auckland in the Department of Engineering Science and Biomedical Engineering. From 2019 to 2024 Mark was the Associate Dean (Research) for the Faculty of Engineering and is also the Deputy Director at the Centre for Advanced Materials Manufacturing and Design.

7 October: Christoph Hartmann

Engineering Food for All

Abstract

The food system faces global socio-economic challenges. Population growth, environmental pollution, climate change and water scarcity put pressure on the agro-food system globally and hence food security and access to nutrient dense food for all are at risk [[i], [ii]].

If larger parts of the global population shift towards plant-based nutrition, the environmental footprint of food and agricultural production will shrink significantly, and public health concerns will reduce. However, this pathway is only viable if consumers accept and can afford healthy plant-based diets on the longer term.

We present challenges related to the sensory unpleasantness of high-protein plant-based nutrition solutions. From the interaction between food and the human perception physiology, we engineer back to product processing, formulation [[iii]].

We also highlight challenges from a process engineering point of view of such formats based on yet not fully characterized and mastered ingredients, when produced on established processing unit operations.

While established processing and manufacturing operations are key for affordability and deployment of products at large scale, the food engineering domain requires innovation. Hence, we present two novel pathways for product formulation and processing:

We illustrate challenges and progress made for the use of gas hydrates as a means concentrate liquid foods as an alternative to thermal concentration which requires high inputs of thermal energy and induces alterations in an otherwise native protein structure [[iv]].

Beyond this we see significant potential in “search driven” discovery approaches, which still require development, as their degree of automation is low, the batch size of each trial is big, and analytical methods are slow, as will be shown in our contribution [[v], [vi]].

The use of robotics, high-throughput assays, artificial intelligence will significantly accelerate this approach and open new opportunities for discovery and development of new nutrient-rich and affordable products.

[i] World Economic Forum: Meat: the Future series, Alternative Proteins, 2019

[ii] World Economic Forum: Innovation with a Purpose: The role of technology innovation in accelerating food systems transformation, 2018

[iii] Assad-Bustillos M., Cázares-Godoy A., Devezeaux de Lavergne M., Hartmann C., Schmitt C., Windhab E., Assessment of the interactions between pea and salivary proteins and their possible role in astringency perception, Innovative Food Science and Emerging Technologies, Volume 83, January 2023, 103290

[iv] Sutter R M, Meunier V, Ruiz S, Doebelin J, Milo M, Rauh C, Hartmann C: Process-Controlled Gas Hydrate Formation in Coffee Solutions for the Application of Cold Concentration, Innovative Food Science and Emerging Technologies, Volume 96, August 2024, 103748

[v] Becker D, Schmitt C, Bovetto L, Rauh C, McHardy C, Hartmann C, Optimization of complex food formulations using robotics and active learning, Innovative Food Science and Emerging Technologies, Volume 83, January 2023, 103232

[vi] D'Oria G; Bredie W. L. P.; Hartmann C.; Limbach H. J. ; Gunes D. Z., Ahrné L. Designing gel coatings for oral soft perception of fiber particles, Food Hydrocolloids, 2024

Speaker Bio:

Christoph holds a degree in mechanical engineering and a PhD in Computational Fluid Dynamics. After his PhD studies, he worked in the automotive industry developing computational mechanics methods for car-crash and occupant safety simulation. In 1998 he started at Technische Universität München, where he pioneered computational engineering methods in food processing, biomechanics and life sciences. He was appointed Associate Professor at Technische Universität München in 2004, and full professor at the German University in Cairo in 2005.

Christoph joined Nestlé in 2006, doing research on the biophysics of in-mouth food breakdown. From 2012, he set up the Nestlé Food Safety Institute in Beijing, and, in 2016, took over the Consumer Science department in Nestlé Research. Since October 2018, Christoph leads Academic Alliances and Expertise Development. He has global responsibility for strategic academic partnerships, internal expert networks, and subject matter expert career development.

In Nov 2019, he was appointed Honorary Professor for Food Process Engineering at the Institute of Food Technology and Food Chemistry of Technische Universität Berlin. In this role, Christoph is active as lecturer and scientist and pursues own research projects in the area of food materials and digitalization.

LinkedIn: https://www.linkedin.com/in/christoph-hartmann-97b07870/

Google scholar: Christoph Hartmann - Google Scholar

14 October: Mark Tibbitt

Dynamic polymer networks for engineered living materials

Abstract

Polymer materials provide solutions to many pressing biomedical, manufacturing, and environmental challenges. However, traditional polymer materials have a limited capacity for rearrangement, presenting difficulties in their processing, use, and recycling. Engineering reversible interactions within polymer networks enables the formation of dynamic and reconfigurable materials, opening new opportunities for use and re-use of polymer networks. In this talk, we will present fundamental insight and applications of dynamic polymer networks with an emphasis on their utility in biomedical applications. We provide a framework for engineering dynamic macromolecular systems by linking molecular behavior at the reversible junctions to macroscopic properties using modeling, spectroscopy, and mechanical characterization. We then present how we use this knowledge to design dynamic biomaterials for scaffolds in photosynthetic living materials for cyanobacteria-based carbon sequestration.

Speaker Bio:

Prof. Mark Tibbitt is an Associate Professor of Macromolecular Engineering at ETH Zurich, where he has been on the faculty since June 2017. Previously, he was an NIH Postdoctoral Fellow in the laboratory of Prof. Robert Langer in the Koch Institute for Integrative Cancer Research at the Massachusetts Institute of Technology. He received his B.A. in Integrated Science and Mathematics from Northwestern University, and his Ph.D. in Chemical Engineering at the University of Colorado Boulder under the supervision of Prof. Kristi S. Anseth. His research integrates concepts from chemical engineering, synthetic chemistry, materials science, and biology to rationally design and assemble soft matter for biomedical applications.

21 October: No Seminar

28 October: Ruth Signorell

Chemical and physical processes in the confined environment of an aerosol particle

Photochemical processes have been

identified as the main cause of the degradation and oxidation of matter in

atmospheric aerosol particles. When light interacts with an aerosol particle,

the light intensity inside the particle can be significantly increased as the

latter acts as a light-amplifying cavity. These optical confinement effects

lead to an acceleration of photochemical reactions in aerosol particles

compared to reactions in extended condensed matter. We studied and quantified

the acceleration of in-particle photochemistry using photoacoustic spectroscopy

[1] and X-ray spectroscopic imaging of single aerosol particles [2].

The

formation of new particles through condensation from the gas phase is an

important source of aerosols. Volatile vapor components can accelerate the

nucleation of other, less volatile vapor components by orders of magnitude. To

investigate the molecular mechanism behind accelerated vapor nucleation, we

developed a new nucleation tool based on Laval expansions combined with soft

cluster ionization [1]. We find that a catalytic cycle involving transient

heteromolecular clusters is the origin of this acceleration phenomenon.

1. J.W. Cremer, K.M. Thaler, C. Haisch, R.

Signorell, „Photoacoustics of single laser-trapped nanodroplets for the direct

observation of nanofocusing in aerosol photokinectics”, Nat. Commun., 7, 10941 (2016)

2. P.C. Arroyo, G. David, P.A. Alpert, E.A.

Parmentier, M. Ammann and R. Signorell, „Amplification of light within aerosol

particles accelerates in-particle photochemistry”, Science, 376, 293-296 (2022).

3. C. Li, J. Krohn, M. Lippe and R.

Signorell, Sci. Adv., 7, eabd9954

(2021).

Speaker Bio:

Ruth Signorell received her MSc and PhD degrees in molecular spectroscopy from the Swiss Federal Institute of Technology (ETH). She began her aerosol research in 2002 as an assistant professor at the Georg-August University of Göttingen. From 2005 to 2012 she was an associate professor and later a full professor at the University of British Columbia in Vancouver, Canada. In 2012 she returned to Switzerland to take up a position as full professor of physical chemistry at the Department of Chemistry and Applied Biosciences at ETH Zurich. Her research interests focus on spectroscopic studies of fundamental processes in aerosol particles and clusters held together by weak intermolecular forces. She is co-editor of a book on the topic “Fundamentals and Applications in Aerosol Spectroscopy (MUOAA)” and co-founder of the aerosol conference “Molecular-Level Understanding of Atmospheric Aerosols”.

4 November : Matteo Seita

Additive Manufacture of Metals with Complex Microstructure

Abstract:

One of the main drivers for the adoption of additive manufacturing (AM) in industry is the ability to build parts with complex—and previously unattainable—geometries. This paradigm has enabled the production of high-performance components with optimized strength-to-weight ratio, or with internal features for enhanced functionality. The disruptive potential of AM, however, goes beyond complexity of shape. Because materials are formed at the microscopic scale following a bottom-up manufacturing approach, AM offers the opportunity to make parts with complex—and previously unattainable—microstructures. Since the relationships between these complex microstructures and the resulting materials properties are difficult to unveil, this unique feature has yet to be capitalized on in current industrial applications. However, it may hold the key to designing the materials of tomorrow. In this talk, I will present a few examples of the microstructure complexity offered by AM which revolve around novel metallurgical strategies to control crystallographic textures, phases, and defects.

Speaker bio:

Dr. Seita is the Granta Design Assistant Professor in the Department of Engineering at the University of Cambridge, where he leads the Additive Microstructure Engineering Laboratory (AddME Lab). The goal of the AddME Lab is to understand and control the microstructure complexity imparted by the additive process to design metallic materials with improved performance and novel functionalities. Before joining the University of Cambridge, Dr. Seita was a Nanyang Assistant Professor at NTU Singapore. During his tenure at NTU, he was awarded the prestigious NRF Fellowship—a S$3M individual grant for early-career scientists—to develop novel additive manufacturing strategies for microstructure control of metal alloys. In recognition of this work, in 2023 Dr. Seita received the TMS Young Innovator in the Materials Science of Additive Manufacturing Award from the Minerals, Metals & Materials Society. He earned his Ph.D. in Materials Science from ETH Zurich in 2012 and then spent three years as a Postdoctoral Associate in the Department of Materials Science and Engineering at MIT. Dr. Seita is the author of over 50 publications and the co-founder and technical lead of the venture XtaLight, which provides simpler, faster, and more affordable microstructure analysis for quality control of metal parts.

11 November: Yves Bréchet

Nucleation of diffusion controlled phase transformations in the solid state, beyond or beside classical nucleation theory ?

First order phase transformations in metallic

alloys may occur in a number of ways, depending if the composition is conserved

or changed, and depending on the mechanisms of structural transformations from

one crystallography to another. When the transformation is diffusion

controlled, it may occur by the amplification of concentration fluctuation (

spinodal decomposition) , or by nucleation and growth of the new phase. The

classical nucleation theory, developed initially for liquids and solids, have

been adapted to solid state transformations in pure metal and binary alloys. In

alloys having more than three elements, where the diffusion coefficients may

differ by orders of magnitude, the situation is more complex, both for the

growth mechanisms , but also for the nucleation mechanisms. Recent experimental

observations and simple calculation show the necessity to revisit classical

nucleation theory in this context.

Speaker bio:

Yves Bréchet is a member of the French Academy of Sciences.

As a specialist in materials science, he got interested both on microstructural evolution in metals and alloys, and on their consequences on mechanical properties, plasticity and fracture. Involved both in fundamental issues such as plastic instabilities and kinetics of phase transformations, he also worked closely with M.F. Ashby on materials selection methods and development of tailored “architecture materials”. In these fields he has authored or co authored 5 books and more than 600 publications.

Professor during more than 30 years in Grenoble University (1988-2012) , he also held the annual chair « Innovation » in college de France ( 2012-2013), and is now res, a research professor in Monash University (Australia) and adjunct professor at McMaster University (Canada). He is currently Scientific director of Saint Gobain compagny, a worldwide Materials industry which is more than 350 years old.

He has held the position of « Haut Commissaire à l’énergie atomique » ( 2012-2018) which is the scientific advisor of the french government for energy related questions.

18 November: Claire Donnelly

Exploring three dimensional spin systems – and beyond

Three dimensional magnetic systems promise significant opportunities for applications, for example providing higher density devices and new functionalities associated with complex topology and greater degrees of freedom [1,2]. Extending to three dimensions allows for the formation of new topologies of spin textures, for example containing defects in 3D such as Bloch point singularities, or truly three-dimensional topological structures such as magnetic hopfions.

In this talk, I will address two main questions: first, can we observe and understand such three-dimensional topological magnetic textures, and second, can we control them?

For the observation and understanding of these three-dimensional textures, we have developed magnetic X-ray tomographic techniques, that open the possibility to map both the three-dimensional magnetic structure [3], and its dynamical response to external excitations [4,5]. In this way, we observe 3D magnetic solitons which we identify as nanoscale magnetic vortex rings, as well as torons that contain Bloch point singularities [6,7].

However, while X-ray magnetic tomography is now a relatively well-established technique, high resolution imaging of extended magnetic systems has so far been limited to rare-earth containing materials. To this end, I will present recent results of soft X-ray dichroic ptychography where the phase dichroism offers a route to imaging magnetic systems that until now have not been accessible [8].

As well as naturally existing within the bulk, 3D spin textures can be introduced and controlled via the patterning of 3D curvilinear geometries [9]. In this way, not only can new states be realized [10], but the energy landscape of topological defects can be designed through the local patterning of curvature induced chirality [11].

This new understanding and control of topological textures in 3D magnetic systems paves the way not only for enhanced understanding of these systems, but also towards the next generation of technological devices.

References

[1] Fernández-Pacheco et al., Nature Communications 8, 15756 (2017).

[2] C. Donnelly and V. Scagnoli, J. Phys. D: Cond. Matt. 32, 213001 (2020).

[3] C. Donnelly et al., Nature 547, 328 (2017).

[4] C. Donnelly et al., Nature Nanotechnology 15, 356 (2020).

[5] S. Finizio et al., Nano Letters (2022)

[6] C. Donnelly et al., Nat. Phys. 17, 316 (2020)

[7] N. Cooper, PRL. 82, 1554 (1999).

[8] J. Neethirajan et al., Phys. Rev. X 14, 031028 (2024)

[9] D. Sheka et al., APL 118, 230502 (2021)

[10] C. Donnelly et al., Nature Nanotechnology 17, 136 (2022)

[11] S. Ruiz Gomez et al., arXiv:2404.06042 [cond-mat.mes-hall]

Speaker Bio

Following her MPhys at the University of Oxford, Claire went to Switzerland to carry out her PhD studies at the Paul Scherrer Institute and ETH Zurich. She was awarded her PhD in 2017 for her work on 3D systems, in which she developed X-ray magnetic tomography, work that was recognised by a number of awards.

After a postdoc at the ETH Zurich, she moved to the University of Cambridge and the Cavendish Laboratory as a Leverhulme Early Career Research Fellow, where she focused on the behaviour of three dimensional magnetic nanostructures.

Since September 2021 she is a Lise Meitner Group Leader of Spin3D at the Max Planck Institute for Chemical Physics of Solids in Dresden, Germany. Her group focuses on the physics of three dimensional magnetic and superconducting systems.

Awards:

2024 Heinz Maier-Leibnitz Prize

2023 ERC Starting Grant

2023 IEEE Magnetics Society 2023 Early Career Award

2020 European Magnetism Association Young Scientist Award

2019 L’Oreal For Women In Science Fellowship

2018 APS Richard Greene Dissertation Award

2018 Werner Meyer-Ilse Memorial Award

2018 ETH Medal

2018 SPS Award for Computational Physics.

25 November: Michael Herbst

Novel mathematics to discover novel materials

Large-scale density-functional theory (DFT) simulations are an indispensable tool to discover novel materials and occupy a noteworthy share of the world's supercomputing resources. Obtaining not only efficient, but also reliable DFT algorithms has thus become of elevated importance: at the supercomputing scale any failing simulations not only waste substantial energy resources, but these failures are also an obstacle to reliable automation and thus overall delay research outcomes. In this talk we will introduce a mathematical point of view on DFT simulations and discuss two examples where mathematical research has contributed to developing especially robust numerical methods for high-throughput screening.

Speaker Bio

Michael Herbst obtained a PhD in Theoretical Chemistry from Heidelberg University in 2018, after which he moved on to two postdoctoral research stays in Applied Mathematics. From 2019 till 2021 he worked with Éric Cancès (École des Ponts, Paris, France) and from 2021 till 2023 he stayed in the group of Benjamin Stamm (RWTH Aachen). Since March 2023 he is an assistant professor in the Institute of Mathematics and the Institute of Materials at EPFL. His current research spans broadly in the field of materials simulations concerning numerical error control and uncertainty quantification of DFT models as well as the development of efficient and robust algorithms for high-throughput materials screening.2 December: Patrick Maletinsky

Quantum sensing for nanoscale materials research and engineering

Quantum two-level systems offer attractive opportunities for sensing and imaging, especially at the nanoscale. In the almost twenty years since its inception, this idea [1] has advanced from proof of concept [2] to a mature quantum technology [3], with broad fields of applications in physics, materials engineering, life-sciences, and beyond.

In this talk, I will present the founding principles and key engineering challenges in the field and highlight particularly rewarding applications of single spin-based quantum sensors. A particular focus will lie on new insights these sensors bring to mesoscopic condensed-matter physics, such as super-conductors [4] or novel magnetic materials. Specifically, I will discuss the use of single-spin quantum sensors to study and engineer atomically thin “van der Waals” magnets [5-7] – an emerging class of magnetically ordered systems that combine fundamental and practical interests and which so far were notoriously hard to address due to their weak magnetization and nanoscale spin-textures.

I will conclude with an outlook on future developments of quantum sensors, such as their use in studying dynamical phenomena in quantum materials [8] or their applications under extreme conditions, such as Tesla-range magnetic fields, or millikelvin temperatures, where new exciting applications wait to be explored.

References:

[1] B. Chernobrod and G. Berman, J. of Applied Physics 97, 014903

[2] G. Balasubmaranian et al., Nature 455, 644; J. Maze et al., Nature 455, 644

[3] N. Hedrich et al. P.R. Appl., 14, 64007; P. Appel et al., Rev. Sci. Instr. 87, 63703; Qnami.com

[4] L. Thiel et al., Nature Nanotechnology 11, 677

[5] C. Gong and X. Zhang, Science 363, 706; M. Gibertini et al., Nature Nano. 14, 408

[6] L. Thiel et al., Science 364, 973

[7] F. Tabataba-Vakili et al., Nature Comm. 15, 4735; Tschudin et al., Nature Comm. 15, 6005

[8] S. Chatterchee et al., PRB 99, 104425Speaker Bio

Patrick Maletinsky is full professor at the Department of Physics of the University of Basel, where he has been active since 2012. He has joined the Department after studies of physics at ETH, the école normal supérieure in Paris and JILA in Boulder, followed by a Ph.D. at ETH Zurich and a postdoc at Harvard University. His main research interests are the development of novel, spin-based quantum sensing technologies and their applications to nanoscience and solid-state mesoscopic physics. Next to applications of quantum sensors to fundamental science questions, he is actively involved in transitioning this emerging technology to industrial applications, in part through the startup company Qnami, which he co-founded in 2017. Prof. Maletinsky received an SNSF starting grant in 2015 and an ERC consolidator grant in 2020; he is currently a member of the Swiss Quantum Commission (quantum.scnat.ch) and head of the Basel Physics Department.

9 December: Meital Reches

Short Peptides and Amino Acids as Building Blocks for Sustainable Materials and Coatings

Abstract:

Short peptides and amino acids are promising building blocks for sustainable materials as they are non-toxic and biodegradable. In this lecture, I will present bio-inspired functional coatings that are spontaneously formed by extremely short peptides and commercially available amino acids. These coatings self-assemble on metals, oxides, and polymers under mild conditions without any need for a curing step and can serve many functions including self-cleaning and antifouling.1 We specifically showed that extremely short peptides can self-assemble into a coating that prevents the first step of biofouling, which involves the adsorption of bioorganic molecules to the substrate.2 The coating significantly reduces the attachment of various organisms, such as bacteria, viruses and fungi, to surfaces.3, 4 Another function that these peptide-based coatings can mediate is the adhesion of mammalian cells to implants. This function is important for the integration of implants into the human body. Moreover, these peptides self-assemble in solution into particles that adsorb and release active compounds that synergistically reduce the number of bacteria, viruses and fungi.5 They can also be integrated into polymeric films by a simple co-extrusion protocol to form active polymeric films.6 Finally, we showed that an individual amino acid can self-assemble into a superhydrophobic coating that can provide surfaces with the ability to self-clean.7

References

(1) Maity, S.; Nir, S.; Zada, T.; Reches, M. Self-assembly of a tripeptide into a functional coating that resists fouling. Chemical Communications 2014, 50 (76), 11154-11157.

(2) Duanis-Assaf, T.; Reches, M. Factors influencing initial bacterial adhesion to antifouling surfaces studied by single-cell force spectroscopy. iScience 2024, 27 (2), 108803.

(3) Hu, T.; Agazani, O.; Nir, S.; Cohen, M.; Pan, S.; Reches, M. Antiviral Activity of Peptide-Based Assemblies. ACS Applied Materials & Interfaces 2021, 13 (41), 48469-48477.

(4) Hu, T.; Kaganovich, M.; Shpilt, Z.; Pramanik, A.; Agazani, O.; Pan, S.; Tshuva, E.; Reches, M. Ultrashort Peptides for the Self-Assembly of an Antiviral Coating. Advanced Materials Interfaces 2023, 10 (6), 2202161. DOI:

(5) Kaganovich, M.; Taha, M.; Zig, U.; Tshuva, E. Y.; Shalev, D. E.; Gamliel, A.; Reches, M. Self-Assembly of a Dipeptide with a Reduced Amount of Copper into Antifungal and Antibacterial Particles. Biomacromolecules 2024, 25 (2), 1018-1026.

(6) Kaganovich, M.; Shlosman, K.; Goldman, E.; Benchis, M.; Eitan, T.; Shemesh, R.; Gamliel, A.; Reches, M. Fabrication of antimicrobial polymeric films by compression molding of peptide assemblies and polyethylene. Chemical Communications 2022, 58 (67), 9357-9360.

(7) Hu, T.; Zhang, Z.; Reches, M. A self-standing superhydrophobic material formed by the self-assembly of an individual amino acid. Journal of Colloid and Interface Science 2024, 655, 899-908.

Homepage – Reches Lab | The Hebrew University of Jerusalem

Speaker Bio:

Meital Reches is a Full Professor at the Institute of Chemistry and the Center for Nanoscience and Nanotechnology, the Hebrew University of Jerusalem. After completing her Ph.D. studies at Tel Aviv University in 2007 and spending three years as an EMBO and an HFSP postdoctoral research fellow at Harvard University, Prof. Reches established her independent research group at the Hebrew University in 2010.

Research in the Reches group focuses on understanding the interactions of biological entities such as proteins, bacteria, viruses, and cells with surfaces. In addition, her group develops peptide-based coatings to control these interactions.

For her innovations, Prof. Reches was awarded with the Marie Currie Alumni Association Best Innovator Award, the Kaye Award and the Tenne Family Prize in Nanoscale Sciences.